Consultations 2021: Understanding the proposed payment mechanisms

24th May 2021

Following a recent deep-dive workshop session with customers, Stuart Hayward-Higham helped us to understand the proposed flow of materials through the new EPR and DRS systems and how new testing requirements will be critical to informing both the evidence chain and the payments made to organisations throughout the system. Here, Stuart summarises some of the key issues discussed and learnings taken.

Payments to local authorities

The modulation process of pricing for packaging items (which is being discussed through a series of DEFRA, WRAP and key stakeholder workshops) will be influenced by the composition of the packaging as under the EPR policy, producers pay more depending on the recyclability of the items or packaging they put on the market. If it is more complex to handle at the recycling stage, the producer would be expected to pay more for its recovery, and this may drive producers to switch materials or reduce the complexity of their packaging over time, which of course will influence what is captured at the kerbside.

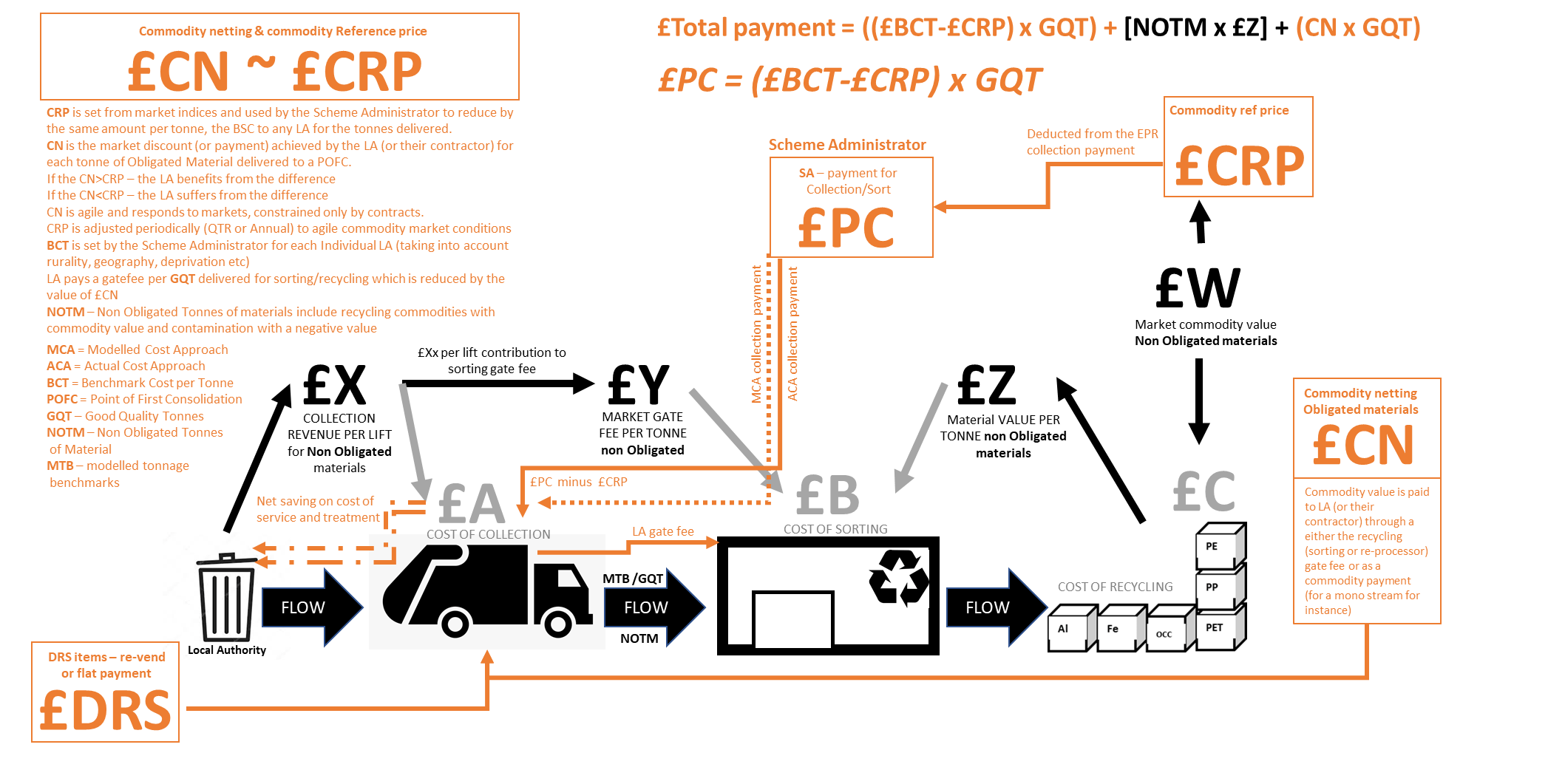

The system of waste collection and management is complex and requires interfaces between the waste producers, collectors, sorting and treatment facilities and end markets for the products produced. With the new policy proposals the composition of the waste collected will change as a result of DRS removing PET plastic beverage bottles, aluminium and steel beverage cans, and possibly glass beverage bottles, and as a result of new materials being added under the consistent collection proposals. The systems of payment will change because of EPR supported costs for obligated packaging items, new burden support for green and food waste collection, and DRS organisation payments for the complete collection, management and treatment system.

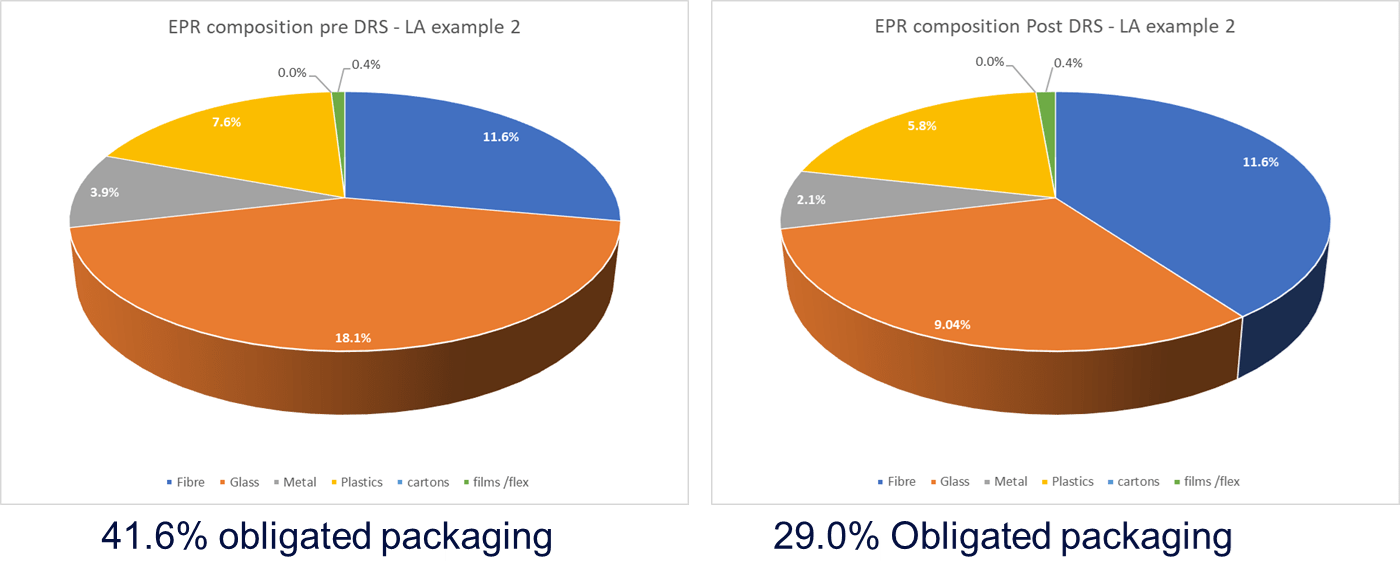

With all journeys, you start by understanding where you are, and in the workshop we spent time looking at the current system and waste compositions. We considered a sample set of different waste compositions coming into one SUEZ sorting MRF and modelled how they might change with the introduction of an all-in DRS system for all three material families. We also discussed how modulation in EPR and format changes induced by DRS might further change composition, and how the respective payment mechanisms might, or might not, adequately manage these potential transitions.

Once there was a common understanding, we moved on to the proposals for the management system and payment structure for municipal, commercial and industrial packaging. We presented and discussed the proposals for municipal residual waste payments and explored the different streams of residual waste from municipal sources where obligated packaging might arise. Given the audience we did not consider the proposals for commercial packaging backhaul and obligation offsetting.

We also considered how the approximately 3.5 billion items of packaging covered by the DRS system but lost to the kerbside systems would be paid for, considering the merits of the three systems proposed and the difficulties with the proposals for re-vending and glass packaging. There was also an interesting discussion around the relative value of the DRS deposit per item, the value in the weight of the material or the EPR payment/evidence value per item. The re-vending deposit is likely to far exceed any weight or EPR payment value but the cost in recovering items from mixed dry waste recycling flows may exceed even that value. Ownership of the materials collected was also studied and the difficulties of having different change of ownership points between the streams of materials in municipal and the three business funding systems when overlain on the existing material flows and management systems were discussed and potential solutions explored. For instance, if a sorting plant is accepting streams of dry recycling from municipal sources and from business sources, and if one of the two business systems with compliance scheme options had been adopted, the different streams in one plant will be owned by two different organisations meaning that they couldn’t be mixed in the processing plant or the product bales without changing the way materials are managed in the plant.

Consideration was given to the items included in municipal payments and how they might be evidenced, and when spending might need to start in preparation for a 2023 launch. For a number of attendees, the fact that we are only one budget year away in the planning process brought a realisation that time is short and there is a lot to do.

The role of the First point of Consolidation (FPoC) in generating evidence on which payments for collection would need to be made was seen to be of great importance, but there was concern that some smaller transfer stations may struggle to have the space to support the necessary sampling and testing. However, it was considered that if the site could keep flows separate or was only dealing with one stream (say dedicated to a single collection authority), then a sorting plant at the next point down the materials management chain could undertake the testing on behalf of the supplying FPoC which could alleviate some of the issues.

With the local authority payment system initially proposed to be based on WRAP modelling and 80% of costs, there was concern that the modelling might not fully reflect the costs of service and questions arose as to whether the costs of transition would be accommodated, especially when they are unknown and therefore more difficult to model. The potential move to ‘actual cost’ was also considered, especially when that could happen in the second year of operation when performance was still being understood and comparative metrics would only be in their early stages.

Business data and payment options

The three proposed payment systems were considered, studying not only the system design but also the data required to support payments and the different points of ownership. None of the three proposed methods were considered to be complete and improvements or changes were identified for all three. There was a general feeling that simple was best, and that a system similar to that proposed for the municipal system might have some advantage, especially if ownership transitions were mirrored between the two. When considering the data provision, we were able to see the extent and granularity of data on samples and material flows already collected for both dry recycling and residual waste streams, and this element seemed less difficult than first thought.

Understanding how the three flows of materials (obligated, non-obligated and contamination) are expected to be managed and how the payment responsibilities flow from the waste producer, through to the re-processor, would work was a key topic of conversation. On option three with the free bin proposal, it seemed difficult to envisage whether this would ever be the case and as such almost all waste producers would need to make a payment related to non-obligated items and contamination. There was some concern that this might undermine the enthusiasm that would arise from a free bin concept.

One area where there was some concern was how would any of the three payment mechanisms be able to distinguish waste producers with large volumes of obligated packaging and those with less, or high contamination, for example. Working through what waste collectors could do on quality assessments before bins are emptied and what onboard weighing might do to identify heavy bins that might be indicative of contamination or large volumes of non-obligated fibre products, for instance.

Time was spent considering the payment mechanisms and how the various data and evidence points supported the payments to collectors and other value chain members, and how discounts on service could be passed back to waste producers. An example of the payment mechanisms discussed is presented below for the municipal system proposed. In this example we spent some time on the workings of the commodity reference price (CRP), the indices such a reference might look to and trust, and how a local authority might contract with elements of the value chain to manage the risk and opportunities with such a mechanism. It was felt that a CRP revision every three months would probably be workable to manage commodity price fluctuations, with the EPR system accommodating larger changes and collectors the risk of movements within the three month revision cycle.

The new collection system that is DRS

Trying to manage the number of different options, from all-in with metal, glass and PET plastic beverage containers, to one without glass, and to one targeted at on-the-go leaves many options to consider in consultation responses. How a local authority can understand the services it will need to operate and amend, and answer the direct and indirect questions in the consultations given the number of options on the table, was deemed a sizeable challenge.

The overall performance of the DRS systems will impact heavily on the materials collected through other channels, and that local authorities in particular would need to plan for a transition where these DRS volumes leave the kerbside collection, and what this might mean for vehicle fleets, types and numbers, for example.

Priority, evidence and performance

Considering the quantum of change required for EPR, consistency of collection and DRS, there was some discussion around what priority might need to be given and which parts might be delayed to allow others to be deployed correctly. Any delay must however be focussed on an interval that is sufficient to allow investments to be paid through, which if they were trucks might be seven years, for example.

The relationship between the quality of the materials and the method of collection, the containers used, the style of collection and the materials collected may become key to decisions being made for service provision in the future, as there will be a minimum acceptable quality standard that must be adhered to for any payments in the EPR system to be made (from collection through to end market). Getting the waste producers, be them householders or employees, to better understand the role they play in getting quantities of quality recycling recovered and therefore achieving the 92% of people doing 92% of the right things 92% of the time is essential in achieving success in these areas and delivering an overall 65% recycling rate.

The evidence local authorities will need

There were a few questions from our customers that focused on their specific circumstances, including how material delivered directly to landfill would fit into the system, and understanding if there would be any pressure to identify the composition of this material. But, as with all materials being processed, it must be subjected to testing and reporting if any payments are to be recovered.

When discussing MRF rejects and how the system manages these it was suggested that if you can prove the obligated packaging has arisen from local authority sources, then these materials will go towards any compensation payments – with the caveat that you would have to deduct compostable packaging as these items are not obligated or paid for in the proposed EPR scheme. This may present some organisations with an incentive to do ‘second sort’ activities on MRF rejects, but this would require testing on the small items rejected to understand the costs or benefits. If MRF systems were inefficient this may be something to consider, but payments for residual stream packaging materials should not exceed recycling payments, as this would incentivise the production of general waste over getting recycling working.

Pulling all this information and understanding into a series of consultation responses will be difficult as the topics are complex in their own right, and are further complicated by the multiplicity of options and inter system relationships that need to be considered. However, making sure we get the systems right for such momentous proposals is imperative.

For more information regarding consultation responses please revisit our consultations feedback webinar recordings.

Blog by Stuart Hayward-Higham, Technical Development Director at SUEZ recycling and recovery UK.

Tweet